How Cobots Are Transforming Small And Medium Manufacturing In 2025

Cobots: A Boon for Workplace Safety

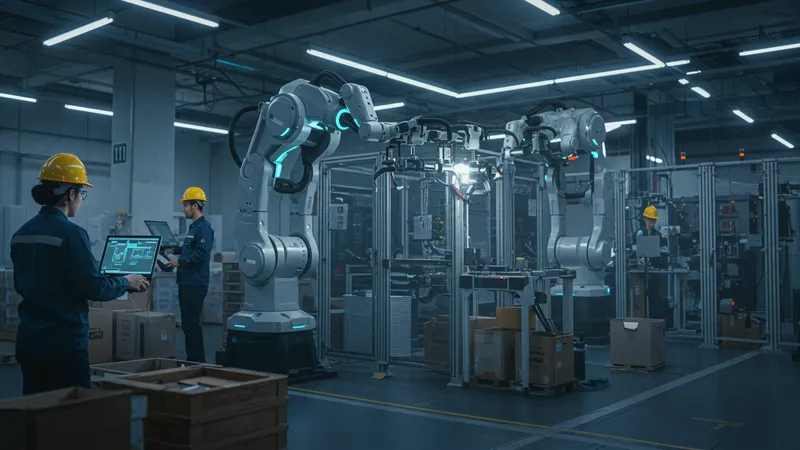

One of the most unexpected yet profound ways cobots are changing manufacturing is through improved workplace safety. While heavy machinery always posed a risk, cobots are designed to work safely alongside humans. Those with in-built sensors detect human presence, drastically reducing workplace accidents.

By handling hazardous or repetitive tasks, cobots lessen human exposure to potentially dangerous situations. They take on roles in environments that pose risks, allowing human workers to focus on supervisory and oversight roles instead. This transference of physical risk to machines has led to a decline in workplace injuries, boosting morale and reducing insurance costs.

The human-centered design of cobots ensures that they are not intrusions in the workplace, but rather contributors to an environment that’s not just efficient, but also safe. Furthermore, ergonomic stress is reduced, leading to a healthier workforce overall. However, companies must still navigate safety standards and compliance, which continue to evolve with the technology.

As businesses weigh these benefits, the undeniable truth remains: cobots offer an opportunity to transform safety standards within manufacturing. This tale of transformation isn’t over; there’s more to discover about the unforeseen advancements these machines bring…