Factory Automation Tools

The Rise of Digital Twins: A Game-Changer in Factory Settings

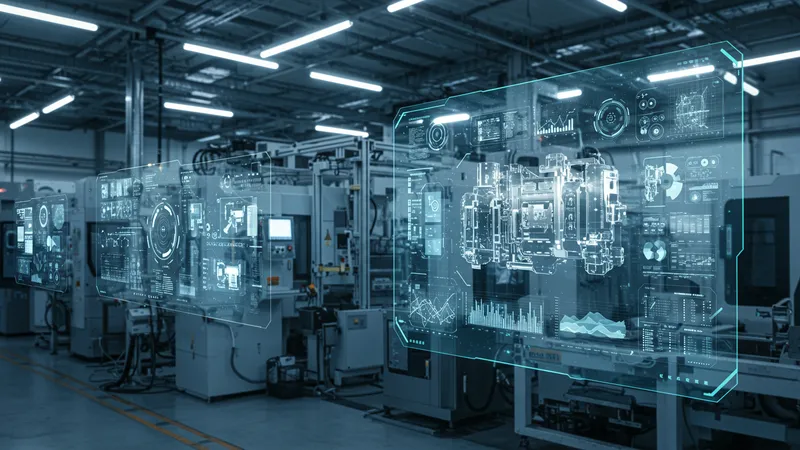

Digital twins are revolutionizing the industry in a way that doesn’t just tweak efficiency—it redefines it. By creating a virtual replica of physical assets, processes, or systems, companies are now able to simulate and optimize production lines without disruptive testing. This technology is making waves, with early adopters reporting a double-digit productivity increase almost overnight.

What makes digital twins a hot topic is their unprecedented ability to provide analytical insights. Factories utilizing this tech can identify areas for improvement that would have otherwise been invisible. Imagine pre-empting issues that would have cost millions if left undetected.

A significant benefit is in predictive maintenance. While traditional approaches react after a failure, digital twins foresee disruptions, and solutions are preemptively fine-tuned, saving time and resources. This approach not only avoids costly downtime but also extends machinery longevity, something unheard of in traditional factories.

Yet, the question remains: as digital replicas become commonplace, are businesses becoming too reliant on technology that could temporarily cripple operations if it fails? The answer might surprise you, as we delve deeper. Keep reading, and prepare to view manufacturing in a new light.