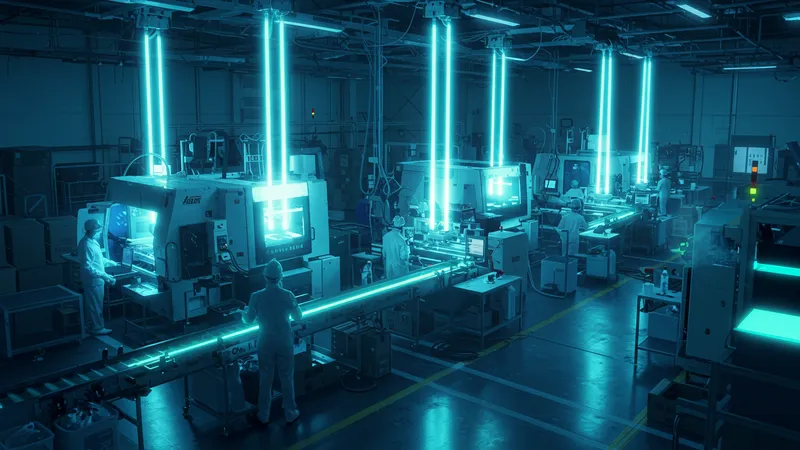

Imagine a world where manufacturing speeds triple overnight. UV curing solutions are not just changing the game; they are redefining it. And what if I told you that this technology is more accessible than you think?

In today's fast-paced world, the need for efficient manufacturing solutions has never been more critical. Companies are scrambling to adopt UV curing for a competitive edge. But why is this the buzzword in every boardroom?

UV curing isn’t just about speed; it’s about precision and sustainability. Many don’t know it, but this technology is cutting down on energy use globally. By emitting zero VOCs, UV curing protects the environment in ways traditional methods can’t. But that’s not even the wildest part…

What if I told you that UV curing not only speeds up production but also enhances product quality? Traditional curing methods expose products to inconsistencies and defects. With UV technology, you get flawless finishes—every single time. But again, that's just scratching the surface…

This revolutionary shift in manufacturing could change how everything is made. From cars to coffee machines, UV curing is quietly reshaping entire industries. What happens next shocked even the experts…

While many manufacturers are aware of the speed and efficiency of UV curing, there’s a hidden benefit that goes unnoticed. UV curing significantly reduces the emission of volatile organic compounds (VOCs), which are notorious pollutants. VOCs contribute heavily to environmental pollution and smog. By reducing or entirely eliminating VOC emissions, UV curing solutions allow companies to meet stricter environmental standards effortlessly. It's an unsung hero for both the planet and the bottom line.

A study revealed that companies adopting UV curing have seen a 25% reduction in energy costs. This is primarily because UV curing requires less energy compared to traditional thermal curing processes. The implications are staggering for industries facing rising energy prices. Saving on costs without compromising quality? That sounds like a win for businesses seeking sustainability. But there’s one more twist—many are still unaware of these potential savings.

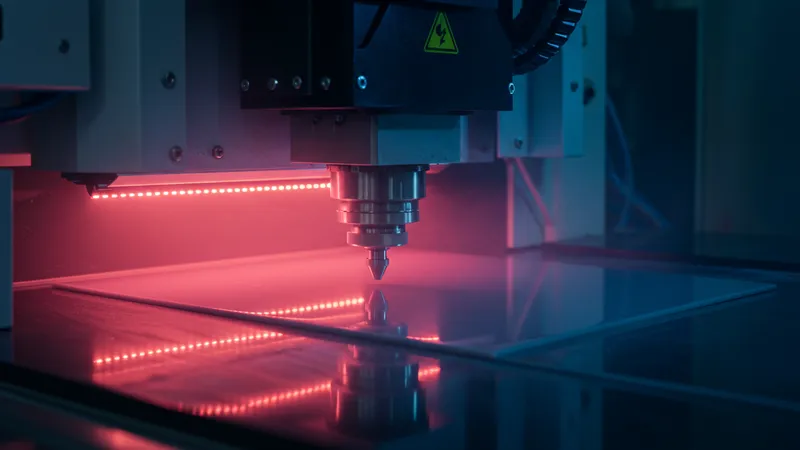

The precision achieved through UV curing is unparalleled. Precision comes not just in curing speed but in the consistency of cured outputs. When defects lead to expensive reworks and wasted materials, consistency becomes key. Quality control becomes less of a headache as products meet specifications more reliably. What you read next might change how you see this forever. Did you know some companies even report a 90% decrease in product defects? The statistics are as impressive as they are surprising.

And for suppliers, the benefits stretch even further! Clients increasingly favor environmentally friendly suppliers, and using UV curing solutions places businesses directly in line with this value. The shift can also be a major factor in winning contracts with eco-conscious companies. Given this invaluable advantage, how many businesses are still clinging to outdated processes?

One unexpected way UV curing stands out is by cutting operational costs dramatically. Traditional methods often require extensive setups, and prolonged downtimes can dwindle productivity. UV curing, on the other hand, allows for lean operations due to its compact nature and rapid results. Businesses report reducing their operational costs by up to 30% by transitioning to UV curing solutions. That’s money saved that can be reallocated to other mission-critical areas.

But the cost-saving doesn’t end there. UV curing improves throughput, the rate at which products can be manufactured and moved along in the production line. With the reduced cycle times, companies can produce more units in less time—leading directly to increased revenue potential. Imagine the possibilities when a factory can run multiple product lines simultaneously without fearing quality deterioration.

The reduction in labor costs is another side benefit. With quicker setup times and reduced manual intervention, companies can streamline their workforce for optimal performance. It's not about cutting jobs but reallocating labor resources to more skill-intensive tasks that align better with human capabilities. This strategic labor shift can lead to higher employee satisfaction and innovation-driven company culture.

More broadly, UV curing technology reduces maintenance costs, largely because the equipment tends to be less prone to wear and tear compared to equipment used for thermal curing processes. How many businesses are currently incurring unnecessary maintenance costs just because they haven’t explored this breakthrough technology?

The environmental advantages of UV curing can't be overstated. Unlike conventional curing methods that consume vast amounts of energy and produce harmful emissions, UV curing is a champion for sustainable practices. Studies have shown that adopting UV curing can lower carbon footprints by significant margins. This move not only cuts costs but aligns companies with the growing global call for sustainability.

Further, UV curing technologies save on material consumption. Traditional methods often result in higher wastage during production, but UV curing's precision reduces material spoilage significantly. This reduction not only conserves resources but also lowers expenses linked to material procurement. It's environmental responsibility and financial prudence rolled into one compelling package.

Insights from industry insiders reveal that adopting environmentally friendly technologies like UV curing can enhance a company’s market image. In an age where consumer consciousness about environmental impact is at its peak, companies leveraging eco-friendly processes can enjoy a distinct advantage. Brands are increasingly evaluated based on their sustainability practices—affecting everything from sales to stock prices.

Yet, as beneficial as it is, many businesses hesitate to transition to UV curing due to misconceptions about initial costs or complexities. However, as more case studies emerge showcasing successful implementations, these myths are being debunked rapidly. When will they realize that their hesitation is costing them more than they imagine?

UV curing technology is a potent secret weapon for enhancing product quality. The evidence lies in the technology's ability to produce seamless finishes consistently, thereby elevating product appearance and durability. Customers noticing these enhancements are more likely to associate the brand with quality, boosting brand loyalty and market reputation.

The high-intensity UV light used in curing provides excellent depth of cure and bonds coatings or inks evenly across surfaces. This ensures not just superior aesthetics but also improved mechanical properties, such as increased scratch and chemical resistance. It becomes a powerful USP for brands marketing high-performance products against their competitors.

Experts point out that the reduced risk of contamination during the UV curing process contributes significantly to the overall product quality. Dust and debris often settle on substances cured via traditional methods, leading to imperfect and rejected outputs. The swift nature of UV curing minimizes air exposure time, ensuring cleaner, defect-free results.

Despite these clear advantages, many manufacturers remain trapped in traditional practices due to unfamiliarity or scepticism towards new technologies. However, as promising case studies illustrate the benefits of UV curing, the question shifts from why make the change to why not. How long can businesses afford to ignore this evident truth?

UV curing isn’t just transforming traditional manufacturing; it is making waves in the world of electronics as well. The precision, speed, and minimal thermal load characteristic of UV curing are essential for delicate components used in electronics, where heat can cause damage or premature aging. By reducing thermal stress, UV curing extends the lifespan of electronic components, a crucial factor for consumer electronics.

Moreover, UV-curable adhesives are now widely utilized in electronics for their rapid bonding capabilities. They enable innovations like smaller device footprints and more complex designs, with manufacturers benefitting from quicker assembly times and lower rejection rates. Industry insiders note that these adhesives are becoming integral to product miniaturization trends.

A significant advantage in the electronics sector comes from UV curing’s adaptability to different materials and surfaces. The technology is versatile enough to work across various substrates, whether it’s glass, plastics, or metals. This adaptability ensures high surface energy and better adhesion, crucially important for cutting-edge electronics.

With electronics continually pushing boundaries in terms of size and functionality, the need for efficient, reliable manufacturing processes like UV curing becomes apparent. More sectors are asking, when will they step up to the latest methods to cement their place in the rapidly evolving tech landscape?

In the aerospace industry, precision and reliability are non-negotiable. UV curing technology meets these crucial standards by creating lightweight, durable components faster than conventional techniques. With airlines constantly under pressure to reduce weight for efficiency, UV curing presents a viable way to achieve significant weight savings without compromising material integrity.

Moreover, UV curing allows for immediate inspection of finished components, reducing the need for lengthy quality checks post-production. In an industry where time equates to cost-intensive downtime, the speed advantage of UV curing is vital. Faster production cycles mean quicker deployment and integration in aircraft manufacturing.

In addition, the aerospace sector demands stringent adherence to safety and environmental regulations–two realms where UV curing excels. The process produces minimal emissions and waste, making it environmentally friendly and compliant with global standards for sustainability. This advantage positions UV curing as a method that meets the industry's regulatory and ecological responsibilities.

As aerospace companies increasingly focus on sustainability, adopting UV curing presents a promising path forward. Many are now closely studying how this technology can revamp their production parades. Are we on the brink of broad-scale transformation in aerospace manufacturing fueled by this dynamic method?

The automotive industry has been quietly investing in UV curing technologies, and with good reason. The efficiency of UV curing aligns perfectly with the industry's consistent demands for rapid yet high-quality production. UV curing processes reduce the time needed to paint and finish car components, making the production line faster and more efficient.

Distinctive customizations in automotive finishes often benefit from the versatility of UV curing. The technology supports vibrant colors and durable finishes that withstand environmental wear, appealing to consumers seeking personalization and longevity in their vehicles. It provides a reliable, repeatable method for achieving consistency in design and feel.

Insiders reveal that using UV curing in automobile production can reduce VOC emissions—a goal for every car manufacturer aiming to meet stringent environmental laws. Lower emissions transform the production process from a major environmental offender to a far more compliant operation, boosting a brand's environmental credentials.

The cost benefits, speed enhancement, and quality improvements driven by UV curing are transforming automotive manufacturing. As the push toward green and efficient production escalates, the burning question is whether the majority of the industry is ready to make a sweeping change to capitalize on these undeniable advantages.

The healthcare industry isn't the first you'd suspect of using UV curing, yet its role here is expanding impressively. From medical devices to healthcare products, UV curing ensures sterile, contamination-free, and high-quality solutions—a necessity when safety is paramount. This technology enhances efficiency without compromising quality, making it especially relevant for high-precision instruments.

UV technology has been utilized in producing items as diverse as syringes and complex, custom-designed prosthetics. Its ability to provide quick curing times ensures a faster turnaround for essential equipment, an absolute necessity in situations where timely medical response is critical. This efficiency translates into better healthcare delivery systems overall.

Further advantages include significant cost savings in manufacturing and waste reduction. By minimizing the need for additional materials and reducing production inconsistencies, UV curing decreases costs and improves margins. It's becoming an alluring aspect for healthcare manufacturers, seeking to balance tight budgets and high-quality output.

As more healthcare manufacturers start to adopt this technology, we’re left to wonder why others remain steadfast in their old ways. What will it take for this sector to realize the game-changing potential that UV curing solutions offer for their everyday procedures?

The fashion industry, always on the hunt for what's next, is exploring UV curing technology. With clothing and textiles demanding vibrant colors and high durability, UV curing provides an edge by offering impeccable finishes and faster treatment times. What traditionally took days—with a risk of color fading or inconsistency—can now be done in a matter of hours.

UV curing’s minimal environmental impact is an attractive feature for the fashion industry, which faces criticism for water consumption and chemical use. By reducing water use and eliminating harmful chemical byproducts, UV curing offers eco-friendly manufacturing of textiles, an advantage increasingly demanded by conscious consumers.

Moreover, this technology opens doors to innovative material treatments and fabric designs impossible with traditional methods. From glowing fabrics to UV-cured coatings that enhance stain resistance, brands can offer functional, stylish pieces that speak to both aesthetics and utility. This shift could spell new fashion trends that leverage technology to capture the changing consumer demands.

As this technology gains traction in fashion circles, it pushes the industry toward sustainability while maintaining creativity and quality. Now the question is, are fashion houses ready to make this technological leap and lead the way in eco-conscious style?

The food packaging industry is another area where UV curing is making unexpected strides. This application ensures package integrity, particularly important for shelf stability and maintaining food quality. Swift and effective UV curing processes can seal and prepare packaging instantly, decreasing turnaround times, which is critical for perishable goods.

UV-cured coatings in food packaging offer enhanced barrier properties against moisture and oxygen, thus extending the shelf life of food products. This preservation capability contributes significantly to reducing food wastage—a crucial consideration in global food distribution and sustainability efforts.

Adopting this technology minimizes the production of harmful emissions, allowing manufacturers to maintain food safety standards strictly. The increased demand for sustainable packaging aligns perfectly with UV curing processes that cut down on environmental impact. A smooth blend of safety, speed, and eco-friendliness makes this technology a preferred choice.

Despite clear benefits, some companies delay integrating UV curing technology due to misconceptions about its complexity or compatibility. Yet with every successful implementation, such doubts dwindle. When will the industry standards shift definitively towards UV-curing solutions for sustainable and efficient packaging?

In the printing industry, UV curing is rewriting the rulebook for quality and speed. Offering immediate drying times and adaptability over various substrates, this technology has enabled high-speed printing without sacrificing quality, fostering advances in newspaper and magazine production, as well as packaging and labels.

Traditional inks take significant time to dry, leading to production slowdowns and increased handling times. By contrast, UV-cured inks set instantly, reducing the risk of smudging and allowing for faster, uninterrupted production flows. This efficiency cuts down on labor costs and enables printers to meet demanding delivery schedules easily.

Beyond speed, UV curing helps achieve superior print quality. The finished product responds better to finishes and displays sharper, more vibrant colors. High gloss, and special finishes become straightforward, and the technology opens the door to personalization, appealing to savvy marketers looking to leverage print for brand communication.

The print industry stands on the cusp of widespread UV curing adoption, but misconceptions remain a barrier. How will they eventually overcome the inertia of the past to embrace the enticing prospects that UV technology offers?

Renewable energy sectors, particularly solar energy, find UV curing a burgeoning asset. The technology aids in fabricating essential components like solar panels, where fast, effective, and equally distributed curing strengthens the durability and efficiency of photovoltaic systems. UV curing’s role is crucial as the demand for reliable and long-lasting solar panels escalates globally.

In wind energy, UV technology assists in the production of large wind turbine blades, ensuring surface integrity and durability. The precise application and rapid curing of protective layers increase blade lifespan and efficiency, directly affecting energy yield and reducing maintenance costs for operators.

Additionally, UV curing supports the ongoing push towards sustainable and clean energy production by minimizing environmental impacts throughout manufacturing processes. Renewable energy companies can seamlessly align their product's green credentials with UV-curing’s ecological benefits, ensuring consistency in sustainable operations.

While the synergy of UV curing and renewable energy appears clear, adoption remains sporadic. What measures will incentivize broader adoption? Could regulatory encouragement stimulate these industries to recognize the compelling benefits at hand?

The pharmaceutical industry is constantly searching for ways to improve production efficiency while maintaining stringent quality standards. UV curing is an innovative solution—aiding in ensuring sterility and enhancing the production of various medical products. The technology supports quick and safe packaging processes, from blister packs to bottle labels.

Pharmaceutical coatings crafted with UV curing not only meet industry standards for safety and performance but also offer customizable release profiles for active ingredients. This customization allows for significant innovation in drug formulation and delivery, addressing precise therapeutic outcomes which are essential in modern medicine.

Moreover, UV curing reduces waste in drug production and packaging, pulling down manufacturing costs—an advantage for companies navigating tight profit margins and regulatory compliance. The eco-friendly nature of UV curing aligns with the industry's growing emphasis on sustainable practices without compromising quality or safety.

While the technology’s benefits are vast, it remains underutilized in pharmaceuticals. What strategic shifts are needed to integrate UV curing broadly, and what could it mean for future drug development processes and efficiencies?

The UV curing revolution is unfolding across diverse industries, pushing boundaries with its blend of efficiency, quality, and sustainability. As companies across the globe embrace this paradigm, the gap widens between those who adapt and thrive versus those who cling to outdated methods. The choice is stark yet simple: innovate with UV curing technology or risk falling behind in a competitive, modern market. This shift not only saves costs but aligns with environmental commitments—a dual benefit that no forward-thinking company can afford to ignore.

Are you ready to embrace the future of manufacturing with UV curing solutions? Share this article, spread the insights, and catalyze the change your industry needs. Bookmark this revolution, and let's step into a brighter tomorrow—together.